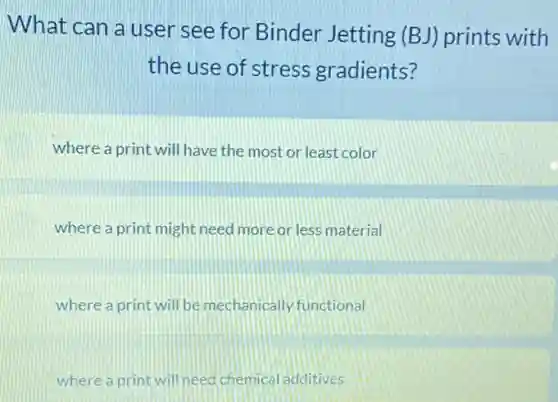

What can a user see for Binder Jetting (BJ) prints with the use of stress gradients? where a print will have the most or least color where a print might need more or less material where a print will be mechanically functional where a print will need chemical additives

Solution4.1(223 votes)

Answer

Explanation

Similar Questions

2. How many horr's does the typical car have? 1 2 3

What is the requirement for a single transducer to offer varying frequencies? Narrow bandwidth Wide bandwidth Mechanical steering Multiple rows of piezoelectric element in the elevational plane

The __ is used most frequently for amperage checks. a. hot-wire ammeter b. integrated ammeter c. clamp-on ammeter d. alternating ammeter

Which of the following are examples of generating the workpart geometry in machining as opposed to forming the geometry (two best answers): A broaching B contour turning C drilling D profile milling E thread cutting

Ride height is being discussed. Technician A says that ride height can be checked regardless of tire brand, size, or inflation values. Technician B says that ride height can be measured with a fully loaded trunk. Who is correct? Select one: a. Technician A b. Technician B c. Both technicians A and B d. Neither technician A nor B

Some vehicles do have grease fittings installed on them Select one: 8. From the factory b. On aftermarket parts c. Both A and B d. Neither Anor B

Damage to the cradle of a vchicle can force the wheels out of alignment, possibly changing Select one a caster b. camber c. toe d all of the above

The maximum acceptable (not necessarily normal) pressure drop across an inline air filter is __ psi. Maximum drop defines at which point to change the inline filter element out. a. 10 b.8 c. 2 d. 5

Most dispensers have o(n) __ to stop the flow of propone in on emergency. OPD(overflow protection device) hose-end valve alarm shutdown system

PEX pipe has a high resistance to what type of water? soft hot hard